Hemp Industry and Sustainable Construction

Academia, New York State government, and industry met for a workshop at Rensselaer last fall to discuss the growing hemp industry and opportunities within the state. The Seed to City Hemp Initiative combines Rensselaer expertise in design, engineering, and business to develop a comprehensive plan for a sustainable and economically viable hemp industry in New York.

New York launched the Industrial Hemp Agricultural Research Pilot Program in 2015, realizing the hemp industry had a potential impact on manufacturing, job creation, and agriculture. Today, the program has nearly 800 authorized growers, and approximately 30,000 acres registered for growing industrial hemp.

“Rensselaer is pleased to be a partner in this exciting effort to develop and commercialize hemp as an industrial product,” says Robert Hull, vice president for research. “Dr. Shirley Ann Jackson announced at President Biden’s virtual climate summit the creation of our Institute for Energy, the Built Environment, and Smart Systems, or EBESS. A major focus of this new Institute will be to create new processes and products that drive decarbonization of the construction industry, in this case by helping to incorporate industrial hemp into New York’s built infrastructure.”

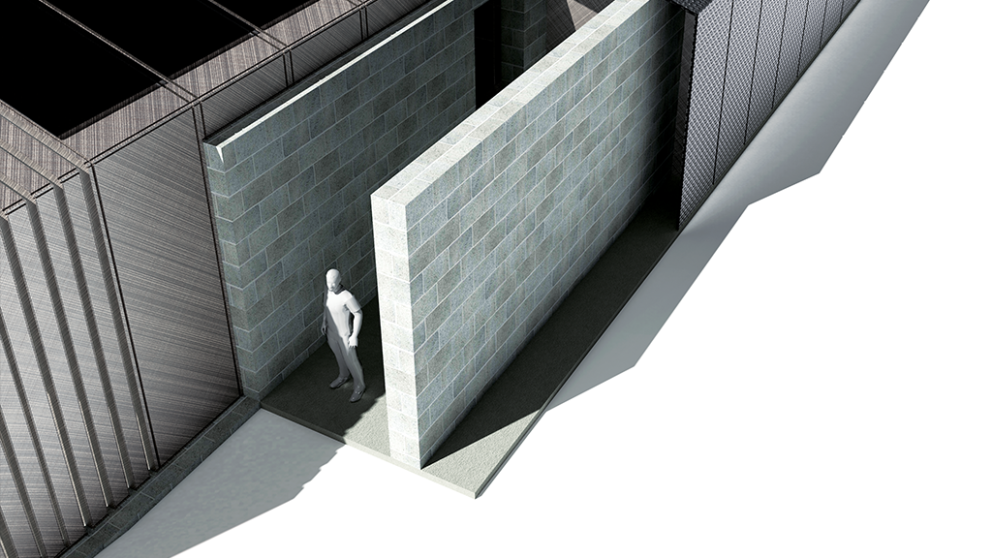

Industrial hemp is a botanical class of Cannabis sativa cultivars grown specifically for industrial or medicinal use. A Rensselaer team is developing several cost-effective hemp processing technologies that separate fiber and hurd — the woody inner core of the hemp stalk — without adversely affecting their mechanical properties. They are also developing a sustainable degumming method and new hemp bio-composite processing methods, as well as a hemp-based rebar reinforcing technology for cement. They are addressing the issues that occur due to steel corrosion by replacing steel with a natural fiber-reinforced thermoplastic rebar. The project aims to extend the lifetime of cement-based buildings and infrastructure.