Robots To Help Manufacture Overflow Health Care Structures

The stress that COVID-19 has placed on medical facilities across the country highlights the need for safe, convenient, and functional surge capacity that can be used for hospital care or quarantine during a public health crisis.

A new research effort led by a team at Rensselaer aims to improve manufacturing of rapidly deployed structures in order to address future shortages of medical care and quarantine facilities, as well as housing needs following a disaster. This project will rely on the development of a group of self-aware, human-directed robots to assist in manufacturing, and is being funded by the Department of Defense through the Advanced Robotics for Manufacturing (ARM) Institute.

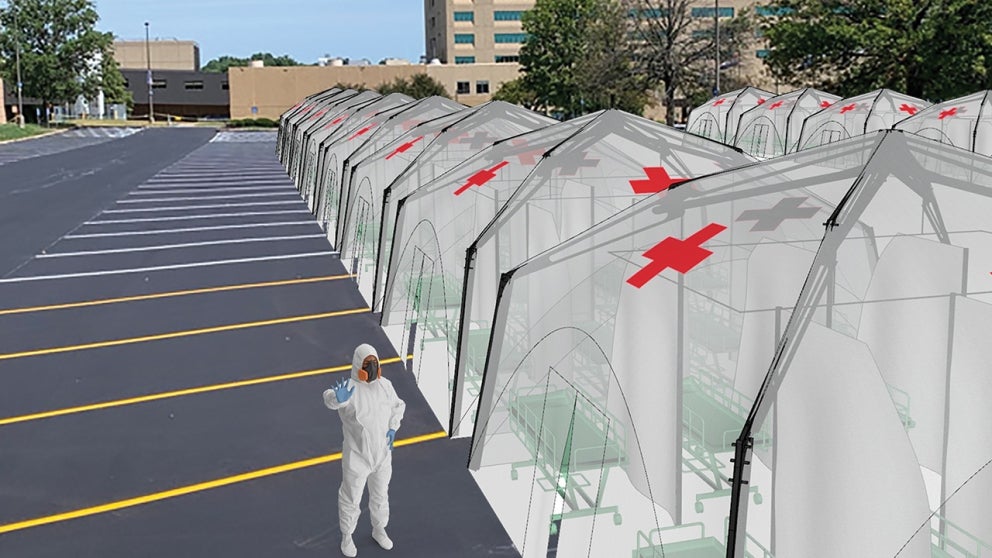

In this project, the Rensselaer team will support Pvilion, a company based in Brooklyn, New York, in producing self-erecting, solar-powered structures that can be configured to suit the needs of a specific mission, including providing critical care, shelter, quarantine, infection control, or other functions. Pvilion is also currently working with the United States Air Force Rapid Sustainment Office.

Manufacturing these structures requires manipulating and joining together multiple pieces of large, heavy, waterproof fabric. The Rensselaer team will design, build, and program a team of small robots that will be capable of holding the material, rotating it, and pulling it taut while it is being heat-sealed together. The robots will work in coordination, guided by humans, as well as software and algorithms that will also be developed and built by Rensselaer researchers.

This research is being expedited within a one-year timeline to address current challenges brought about by the pandemic.

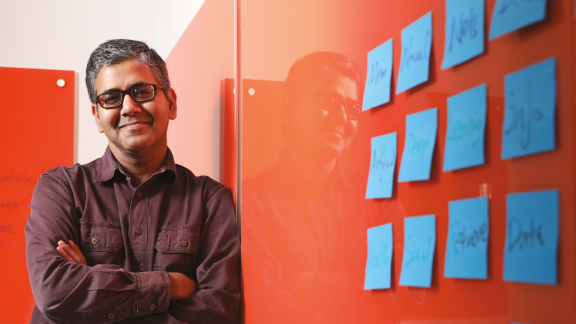

“This project answers a timely challenge in both manufacturing and health care,” says Glenn Saunders, senior research engineer within the Center for Automation Technologies and Systems, who is leading this project with John Wen, head of the Department of Electrical, Computer, and Systems Engineering. “These robots are needed to fill a real void in manufacturing that’s currently present. They will enable faster production of a structure that could give medical teams the extra space they need to respond to a pandemic like the one we’re currently experiencing.”